| This view shows the mechanisms of the Logosol M7 sawmill. The chainsaw is drawn down the guide rail and through the log by reeling in the white nylon cord. At the far end the cord is attached to the guard which is clamped to the rail and has teeth ("dogs") that grip the end of the log. The log is sitting on two log beds that are raised and lowered by turning the crank to reel in or play out the heavy green cords. At the base of the vertical stainless steel bar on the logbed is a set nuts and bolts that allow the log beds to be fine tuned to each other. The bar has teeth that engage a pawl which has two sets of teeth, coarse and fine. Seen below and left of the cord spool, the pawl ratchets into position on the bar with an audible click; the coarse side of the pawl raises the bed in 1/4" intervals, and the fine side raises in 1/8" intervals. The guide rail is two sections totaling slightly over 16 feet long, short extensions are available as well as half mills which add 8+ feet and another logbed. |

|

|

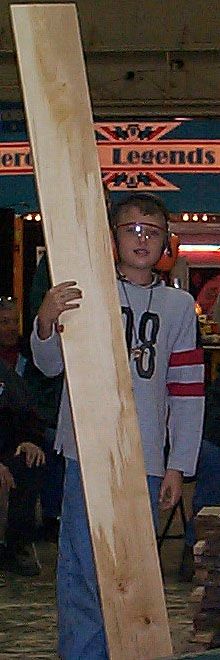

Think he's caught the milling bug? There is nothing quite so nice as lifting off a freshly milled board to expose a bright new layer of woodgrain. |